Preventive Maintenance

Preventive maintenance is a routine task that detects a known failure mode or extends asset life.

Time-based

Time-based preventive maintenance is the most common. Inspections are performed at regular intervals as recommended by original equipment manufacturer or industry best practices.

Meter-based

Meter-based preventive maintenance uses production cycles, rotations, or machine hours to trigger a maintenance task.

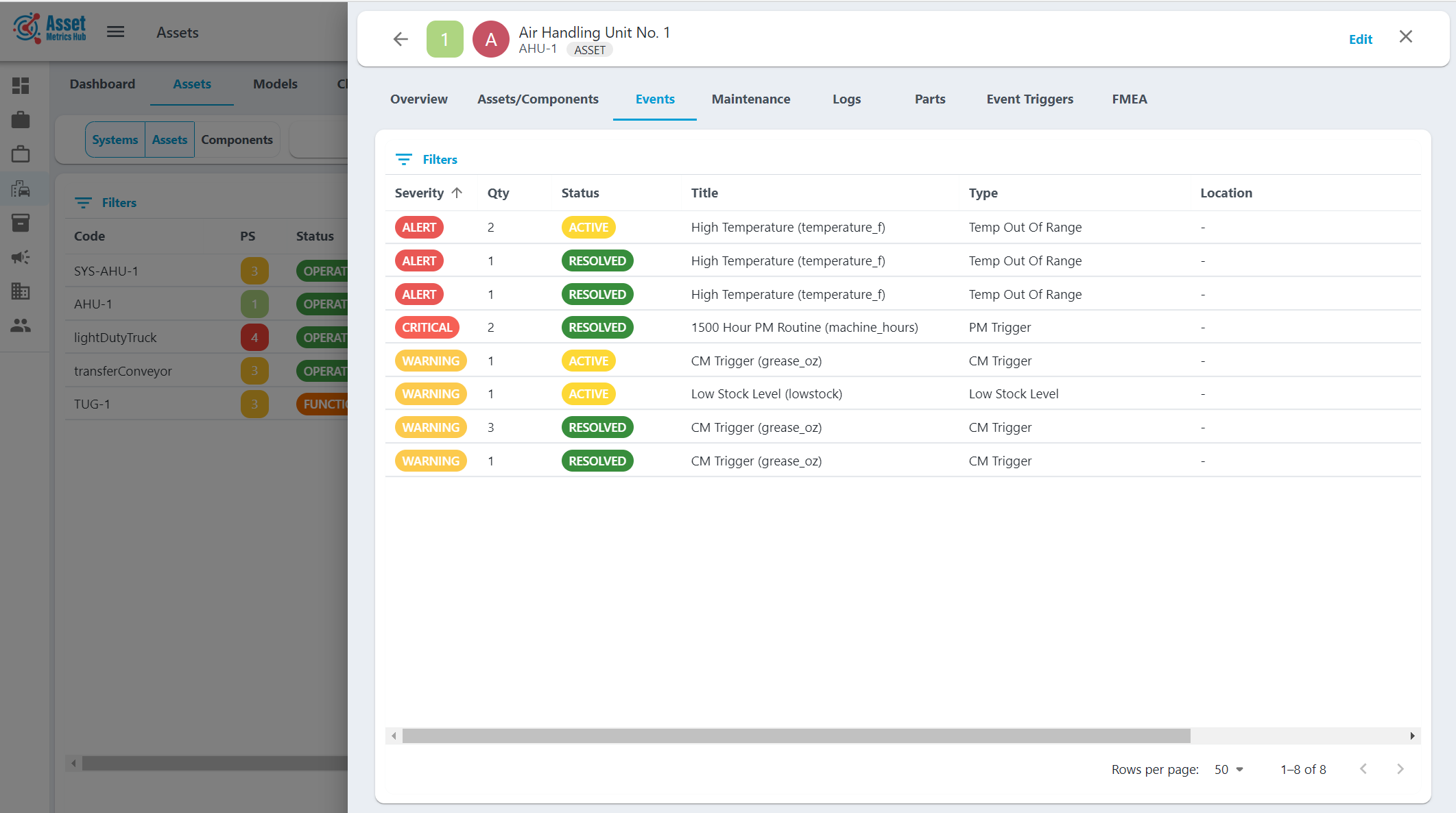

The Asset Metrics Hub automates preventive maintenance tasks using data from machine sensors, scanned documents, and manual data entries. Preventive maintenance reduces costly repairs and increases the availability and utilization of your assets.

Work Management

Initiate, plan, schedule, and execute work orders. Assign maintenance job plans, predefined MRO pick lists, and craft codes to automate work planning. Real-time data collection using our Smart Field Forms integration.

Asset Management

Plug-n-play asset classes and parent/child structures to capture data at the maintainable components.

Time/Cost Tracking

Track time and costs per asset, task, or work order. Report maintenance costs per location, asset, and work order. Identify underperforming assets.

Improve asset uptime with preventive maintenance

Reactive maintenance is defined as repairs performed on an asset that has already failed. Although reactive maintenance is unavoidable and it is an important part of asset management, it could be minimized with preventive maintenance. Preventive maintenance, which...

Ready to streamline maintenance operations?