Reactive maintenance is defined as repairs performed on an asset that has already failed. Although reactive maintenance is unavoidable and it is an important part of asset management, it could be minimized with preventive maintenance.

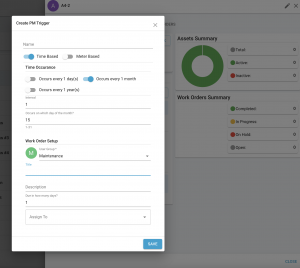

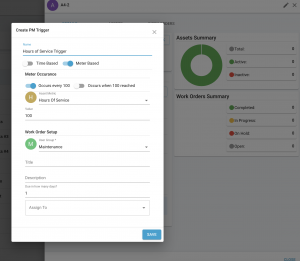

Preventive maintenance, which could be considered a trigger for corrective maintenance, is carried out at regular intervals defined by a manufacturer’s maintenance schedule or industry accepted best practices. Typical Computerized Maintenance Management Systems (CMMS) software provides a calendar for entering asset maintenance schedules. IoT integration platforms provide functionality to automate maintenance tasks with time or meter based events.

Time-Based Preventive Maintenance

Meter-Based Preventive Maintenance

Having automated triggers for preventive maintenance helps eliminate human errors and eliminates the need to manually administer preventive maintenance schedules. When you integrate the Asset Metrics Hub, preventive maintenance is configured by asset type, based on failure modes, and automatically schedules tasks using unified data models.

Performing maintenance at regular intervals eliminates unexpected downtime and reduces costly repair costs.

Let's start the conversation

Asset Metrics Hub offers free consulting to review and evaluate your CMMS and workflow process automation needs.